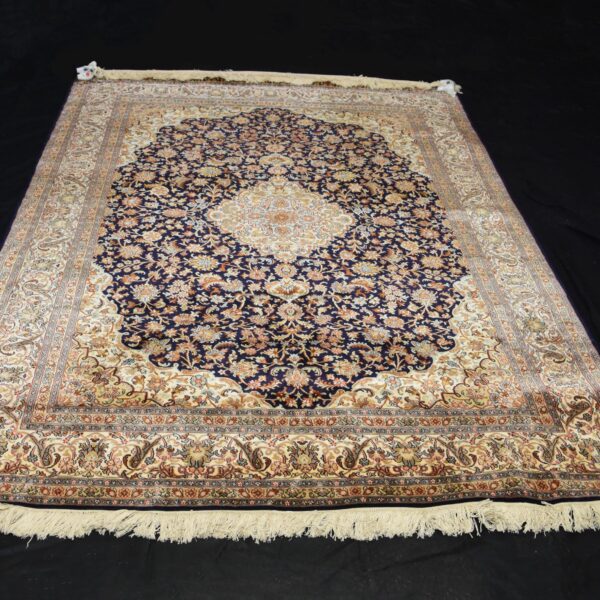

Details

Creating a wool-on-wool Kashmiri carpet involves the use of wool for both the foundation and the pile, resulting in a carpet with a warm and luxurious texture. The process is intricate and requires skilled craftsmanship. Here’s an overview of how a wool-on-wool Kashmiri carpet is typically made:

1. Designing:

The process begins with the creation of a detailed design for the carpet. Skilled artisans draw intricate patterns on graph paper, determining the layout and motifs that will be woven into the carpet.

2. Yarn Preparation:

High-quality wool is used for both the warp (lengthwise threads) and weft (crosswise threads) of the carpet. The wool is carefully cleaned, sorted, and dyed in various colors to achieve the desired palette.

3. Setting Up the Loom:

The loom is prepared for weaving by stretching the wool warp threads tightly, creating the foundation for the carpet.

4. Knotting:

The weaver follows the predetermined design, knotting the wool pile around the wool warp threads. The two main types of knots used are the Persian knot (single knot) and the Turkish knot (double knot), depending on the design and the weaver’s preference.

5. Weaving:

The weaver meticulously follows the design, knotting the wool pile to create the intricate patterns. This process demands precision to ensure that the knots are consistent and densely packed.

6. Shearing:

After completing a section of the carpet, the pile may be longer than the final desired height. The carpet undergoes shearing to achieve the appropriate length, revealing the intricate patterns and creating a uniform surface.

7. Washing and Finishing:

The completed wool-on-wool carpet is thoroughly washed to remove any residual dyes and impurities. Subsequently, it is left to dry in the sun. Additional finishing processes may include stretching, ironing, and adding fringes.

8. Quality Control:

Skilled artisans inspect the carpet for any imperfections, ensuring it meets the required quality and design standards. Corrections or adjustments are made if necessary.

9. Final Inspection and Packaging:

The finished carpet undergoes a final inspection to confirm its adherence to quality standards. Once approved, the wool-on-wool Kashmiri carpet is carefully rolled, packaged, and prepared for shipment.

The result is a luxurious and warm carpet that showcases the craftsmanship and artistry of Kashmiri weavers. Wool-on-wool carpets are highly prized for their intricate designs and the natural beauty of wool fibers.